1. Introduction

Lumen depreciation is a significant concern in LED lighting systems, impacting efficiency, lifespan, and overall performance. Over time, the luminous output of LEDs diminishes, which can lead to inadequate illumination and increased operational costs due to frequent replacements or adjustments. To reduce lumen depreciation in LED lights, it is essential to implement proper thermal management, use high-quality LED chips and drivers, optimize circuit design, and follow regular maintenance practices. Understanding the factors that cause lumen depreciation and implementing effective strategies can extend the lifespan of LED fixtures and maintain optimal lighting conditions. This article explores the causes of LED lumen depreciation and provides actionable solutions to mitigate its effects.

2. What is the Lumen Depreciation Rate of LED?

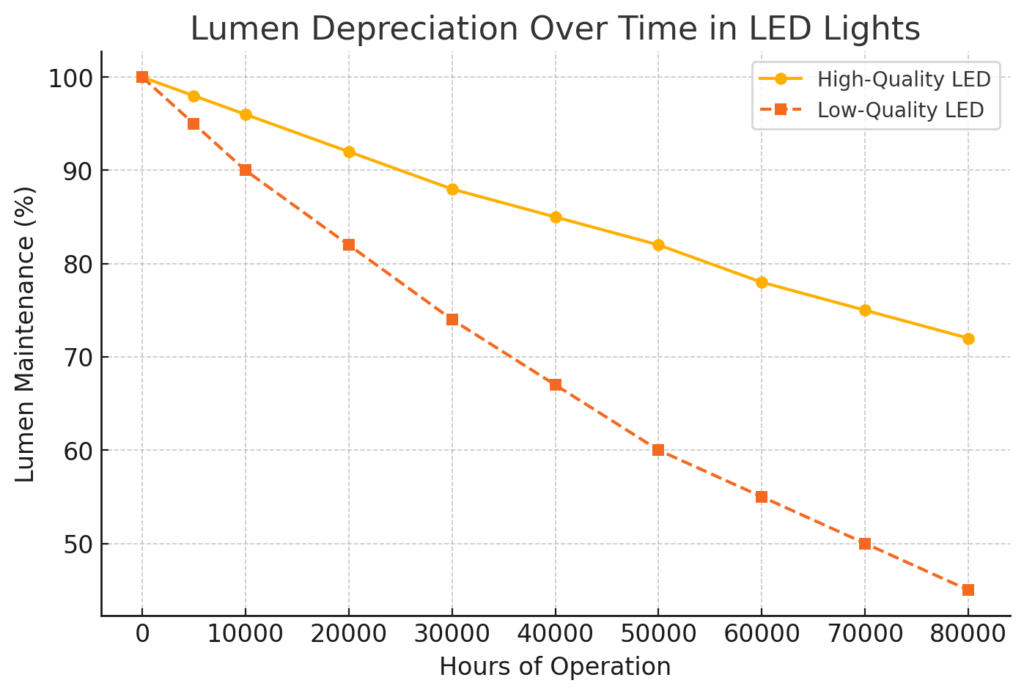

Lumen depreciation rate refers to the gradual reduction in light output over time. It is typically represented by L70, L50, or L90 ratings, which indicate the percentage of the original lumens remaining after a specific duration of use.

For example:

- L70 = 50,000 hours means that after 50,000 hours, the LED will still emit 70% of its original lumens.

- L90 = 20,000 hours means that after 20,000 hours, the LED will still emit 90% of its initial brightness.

Different environmental and operational conditions, such as temperature, voltage, and driving current, influence how quickly LEDs experience lumen depreciation.For a detailed introduction to LEDs, visit this guide.”

3. Key Industry Standards & Testing Methods

3.1 L70, L50, and L90 Ratings

These ratings indicate how long an LED fixture will function before its luminous flux decreases to a specific percentage of its initial output. Higher L70 values indicate longer-lasting performance.

3.2 LM-80 & TM-21 Testing

- LM-80: Measures lumen maintenance over time under controlled conditions.

- TM-21: Uses LM-80 data to project long-term lumen depreciation beyond tested hours.

3.3 IEC 62722 & Energy Star Standards

- IEC 62722 defines performance metrics for LED luminaires.

- Energy Star certification ensures LED efficiency and quality compliance.

4. Causes of Lumen Depreciation in LEDs

4.1 Heat Accumulation & Thermal Management Issues

Excessive heat is the leading cause of LED lumen depreciation. When LED junction temperature (Tj) rises beyond optimal levels, it accelerates the degradation of the phosphor coating and semiconductor materials, reducing brightness.

4.2 Electrical & Driver-Related Issues

LED drivers regulate power supply, and poor-quality drivers can cause voltage fluctuations that overdrive or underdrive LEDs, leading to premature lumen loss.Learn more about LED driver circuits here

4.3 LED Chip Quality & Material Degradation

The quality of LED chips plays a crucial role in determining how well they retain light output over time. Phosphor degradation, poor encapsulation, and subpar chip manufacturing can contribute to rapid lumen depreciation.

4.4 Poor PCB Design & Circuit Optimization

Inadequate heat dissipation due to poor PCB (Printed Circuit Board) layout leads to increased temperatures and accelerates lumen degradation.

4.5 Environmental & Operational Factors

Harsh environmental conditions, such as high humidity, dust, and corrosive substances, contribute to LED degradation. Outdoor LED fixtures require additional protection to withstand these elements.

4.6 What is the Depreciation Rate of LED Lights?

Depreciation rate varies based on factors such as:

- Chip quality (premium vs. low-end LED chips)

- Operating conditions (temperature, humidity, voltage stability)

- Usage intensity (continuous vs. intermittent operation)

Standard high-quality LED fixtures typically have an L70 rating exceeding 50,000 hours, while lower-quality LEDs may experience noticeable lumen depreciation within 10,000-20,000 hours.

5. Effective Strategies to Reduce Lumen Depreciation

5.1 Advanced Thermal Management Techniques

- Use high-efficiency heat sink materials (Aluminum, Copper, Graphene).

- Apply thermal interface materials (TIMs) to improve heat dissipation.

- Implement active cooling strategies such as forced-air ventilation.

5.2 High-Quality LED Components & Manufacturing

- Select LEDs with superior phosphor coatings for longevity.

- Ensure strict quality control during manufacturing.

5.3 Reliable LED Drivers & Power Management

- Choose high-quality constant current drivers to prevent electrical fluctuations.

- Ensure power surge protection to avoid damage from unstable power supply.

5.4 Intelligent Circuit Design & PCB Optimization

- Optimize PCB layout for effective heat dissipation.

- Regulate current flow to prevent LED overstress.

5.5 Constant Lumen Output (CLO) Technology

- CLO adjusts LED power output over time to compensate for lumen depreciation, maintaining consistent brightness.

- CLO improves long-term performance while optimizing energy efficiency.

5.6 How Do I Reduce the Lumens on My LED?

- Adjust LED driver settings to lower brightness.

- Use dimmers and light diffusers to control output.

- Implement PWM dimming, 0-10V dimming, or DALI dimming for controlled lumen reduction.

5.7 Proper Installation & Routine Maintenance

- Ensure proper luminaire positioning to enhance heat dissipation.

- Perform regular cleaning to prevent dust accumulation.

- Monitor driver performance and replace faulty components promptly.

5.8 How to Reduce the Intensity of LED Light?

- Use optical lenses and reflectors to redirect light.

- Employ smart lighting systems for dynamic intensity adjustments.

6. Choosing the Right LED Products to Minimize Lumen Depreciation

6.1 What to Look for in LED Fixtures?

- Opt for LED fixtures with high L70 ratings (50,000+ hours).

- Check LM-80, TM-21, and Energy Star data.

6.2 Avoiding Low-Quality LEDs in the Market

- Beware of LED products lacking certifications or long-term test data.

- Choose brands with established reputations.

6.3 Application-Based Recommendations

- Street Lighting: High IP-rated, UV-resistant LEDs.

- Industrial & Commercial Lighting: Energy-efficient, dimmable LEDs.

- Outdoor LED Fixtures: Enhanced weatherproof designs.

7. Conclusion & Future Trends in LED Technology

7.1 Key Takeaways

- Proper thermal management, high-quality components, and smart circuit design significantly extend LED lifespan.

- Regular maintenance and CLO technology help mitigate lumen depreciation.

7.2 Future Innovations

- AI-powered LED lighting for adaptive brightness control.

- Micro-LED & OLED advancements for superior energy efficiency.

- Next-generation phosphor technology to reduce lumen depreciation rates.

8. Frequently Asked Questions (FAQ)

8.1 How can I extend the lifespan of my LED lights?

Read more about outdoor lighting system maintenance

- Ensure proper heat dissipation and use high-quality drivers.

- Regularly clean and maintain fixtures to prevent dust accumulation.

- Use dimmers to reduce strain on LEDs.

8.2 Why do some LED lights degrade faster than others?

Find the best LED driver brands for street lighting

- Low-quality LED chips, poor heat dissipation, and unstable electrical supply accelerate lumen depreciation.

8.3 Can LED lumen depreciation be reversed?

Discover how to select street lights with the right IK rating

- No, but it can be slowed down by implementing proper maintenance and control strategies.

8.4 Do LED lights lose brightness over time?

Learn about energy efficiency in urban lighting

- Yes, but high-quality LEDs with efficient cooling systems and reliable drivers degrade much slower than low-quality ones.