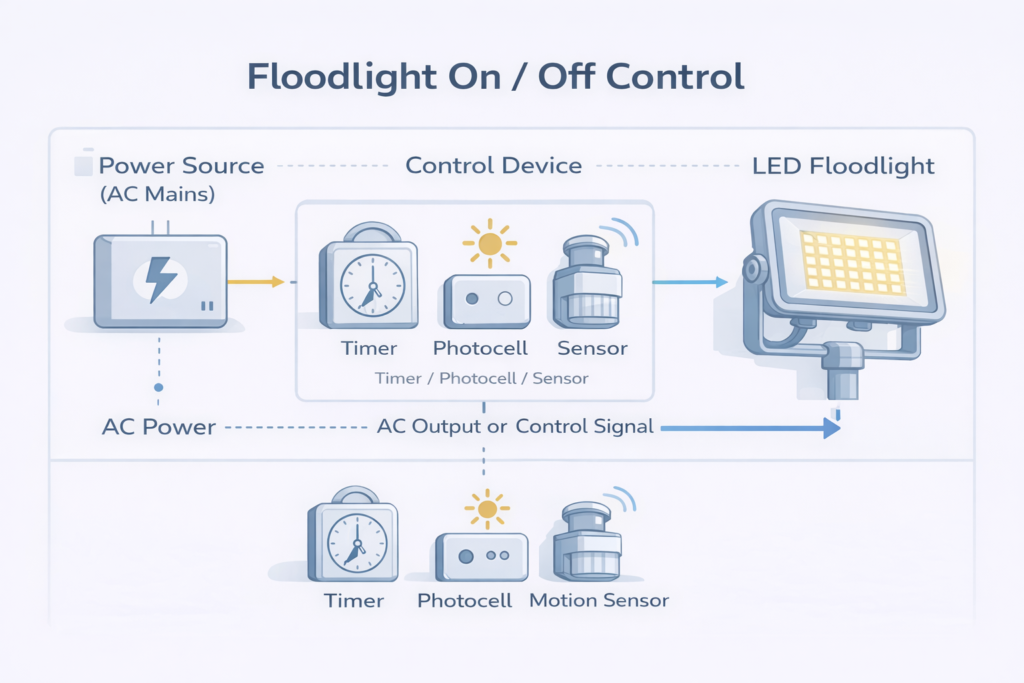

Floodlight on / off control focuses on simple and reliable switching for outdoor lighting applications. It covers timers, photocells, motion sensors, and centralized switching, helping projects achieve stable operation with low maintenance.

Floodlight on / off control refers to the method of switching floodlights fully on or off through external control devices or power control. Unlike dimming systems, on / off control focuses on stable power switching or control signal triggering, making it suitable for most outdoor lighting projects.

In practical installations, on / off control is commonly achieved by cutting or supplying power, or by using external controllers to trigger the LED driver. The control method selected directly affects system stability, wiring complexity, and long-term reliability in outdoor environments.

Different floodlight on / off control methods are used depending on site conditions, control accuracy, and maintenance requirements. The following comparison outlines the most common solutions applied in outdoor lighting projects.

| Control Method | Typical Applications | Advantages | Considerations | Wiring Complexity |

|---|---|---|---|---|

| Manual Switch / Breaker | Small sites, testing, maintenance | Simple, low cost | No automation, manual operation | Low |

| Timer | Facade lighting, signage, yards | Fixed schedule, stable operation | No response to daylight changes | Medium |

| Photocell (Dusk-to-Dawn) | Parking lots, roadsides, perimeter areas | Automatic based on ambient light | Placement affects accuracy | Low |

| Motion Sensor | Security zones, low-traffic areas | Energy saving, on-demand lighting | Risk of false triggering | Medium |

| Contactor / Relay Control | Large-scale installations | Centralized control, scalable | Requires proper surge protection | High |

Control method selection should consider site environment, switching frequency, and outdoor protection requirements.

Typical floodlight on / off control is implemented through different wiring arrangements depending on the selected control device and project scale. Below are common wiring scenarios used in outdoor lighting installations.

Photocell control switches floodlights automatically based on ambient light levels. The photocell is usually installed at an open location to accurately detect daylight and control one or multiple floodlights simultaneously.

USE IN:

Parking areas, perimeter lighting, roadsides

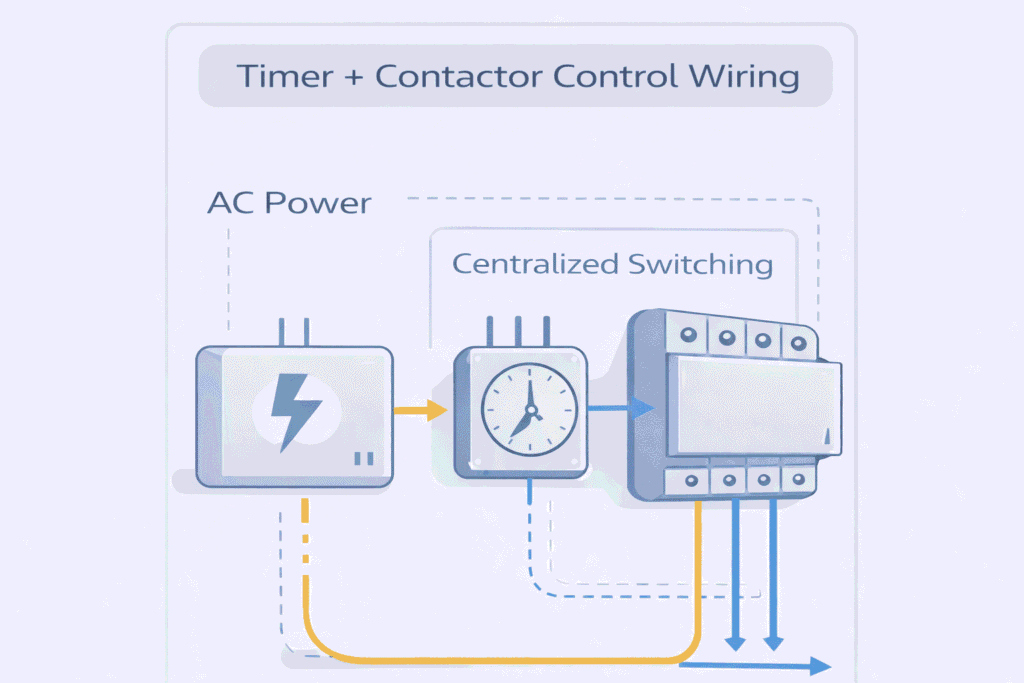

Timer control uses a fixed schedule to turn floodlights on and off at preset times. It is often combined with contactors when controlling multiple floodlights in large outdoor installations.

USE IN:

Building façades, signage lighting, industrial yards

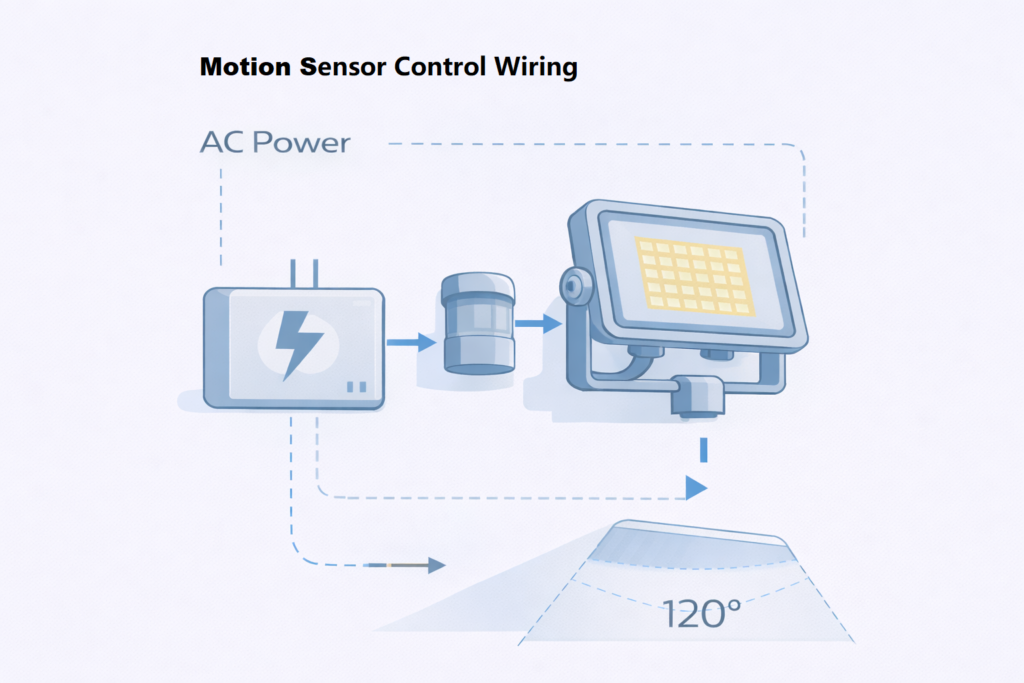

Motion sensor control activates floodlights when movement is detected within a defined area. Proper sensor positioning is critical to avoid false triggering caused by heat sources or reflections.

USE IN:

Security zones, low-traffic areas

Reliable floodlight on / off control in outdoor environments depends not only on the control device itself, but also on wiring design, protection measures, and component compatibility. The following factors should be carefully considered in real projects.

Outdoor switching circuits are exposed to lightning and grid surges. Proper surge protection devices help prevent controller and driver damage during frequent on / off operations.

Poor cable glands or junction boxes often cause moisture ingress. All control wiring should use outdoor-rated connectors to maintain stable switching.

When multiple floodlights switch on simultaneously, high inrush current may stress drivers and contactors. Proper component selection is essential.

Not all LED drivers are suitable for frequent power switching. Driver compatibility should be verified when using external on / off control devices.

Incorrect sensor positioning can lead to false triggering caused by heat sources, reflections, or passing vehicles, especially in outdoor environments.

Controllers and wiring points should remain accessible for inspection and replacement without dismantling the entire lighting system.

As one of the most basic and widely used functions in floodlighting, On / Off control places higher demands on product reliability and supplier quality.

Under long operating hours or frequent switching conditions, the stability of the driver, electrical design, and overall quality management become critical. Our Floodlight On / Off products are built on proven configurations and are supplied with a 5-year warranty, ensuring dependable performance in real projects.

In addition, these products are TÜV CE CB certified, meeting international standards for electrical safety and structural reliability, allowing project owners and contractors to select them with confidence.

Different outdoor applications require different floodlight on / off control strategies. The recommendations below are based on typical site conditions, operating patterns, and maintenance considerations.

Recommended control: Photocell or timer with backup Photocell control ensures dusk-to-dawn operation, while a timer can be used as a secondary schedule for reliability.

Recommended control: Timer-based switching Facade lighting typically follows fixed operating hours, making timer control simple and consistent.

Recommended control: Timer + contactor centralized control Centralized switching allows multiple floodlights to be controlled reliably from a single point.

Recommended control: Motion sensor control Motion-based control provides reliable lighting response in factory environments, supporting safe movement and operational efficiency while minimizing power usage during idle periods.

To ensure a suitable floodlight on / off control solution, the following information is typically required

during project planning and quotation stages.

CTA: Share your project details to receive a suitable on / off control recommendation.

Yes. Photocells, timers, or contactors can be used to control multiple floodlights simultaneously, provided the wiring capacity and load limits are properly designed.

Frequent switching may affect driver components if not properly selected. Using drivers suitable for on / off control and limiting unnecessary switching helps maintain long-term reliability.

Proper sensor placement, correct detection angle, and avoiding heat sources or reflective surfaces are key factors in reducing false triggering in outdoor environments.

Yes. Outdoor floodlight control circuits are exposed to lightning and grid disturbances. Surge protection is strongly recommended to protect controllers and LED drivers.

Yes. Most outdoor floodlights can work with external contactors or relays, as long as driver compatibility and inrush current are considered during system design.

Explore our full LED Floodlight Series and related control solutions for industrial, commercial, and infrastructure projects:

30W Floodlight|50W Floodlight |65W Floodlight | 100W Floodlight | 150W Floodlight | 200W Floodlight | 300W Floodlight| 400W Floodlight | 500W Floodlight| 750W Floodlight | 1000W Floodlight

DALI Dimmable LED Floodlight |Dimmable LED Floodlight |Floodlight ON OFF Control |Timer Control Floodlight |Remote Control LED Floodlight |Smart LED Floodlight |

RGBW Floodlight