1.1. Introduction

The rapid adoption of LED technology in street lighting has revolutionized urban illumination, offering higher efficiency, longer lifespans, and reduced maintenance costs compared to traditional lighting solutions. However, not all LED technologies are created equal. Among the various LED types, Surface Mounted Device (SMD) and Chip On Board (COB) are two of the most commonly used in street lighting applications. Choosing the right LED technology is essential for optimizing energy usage, improving light quality, and enhancing the lifespan of street lighting systems. Learn more about the benefits of LED lighting.

2.1. Understanding SMD and COB Technologies

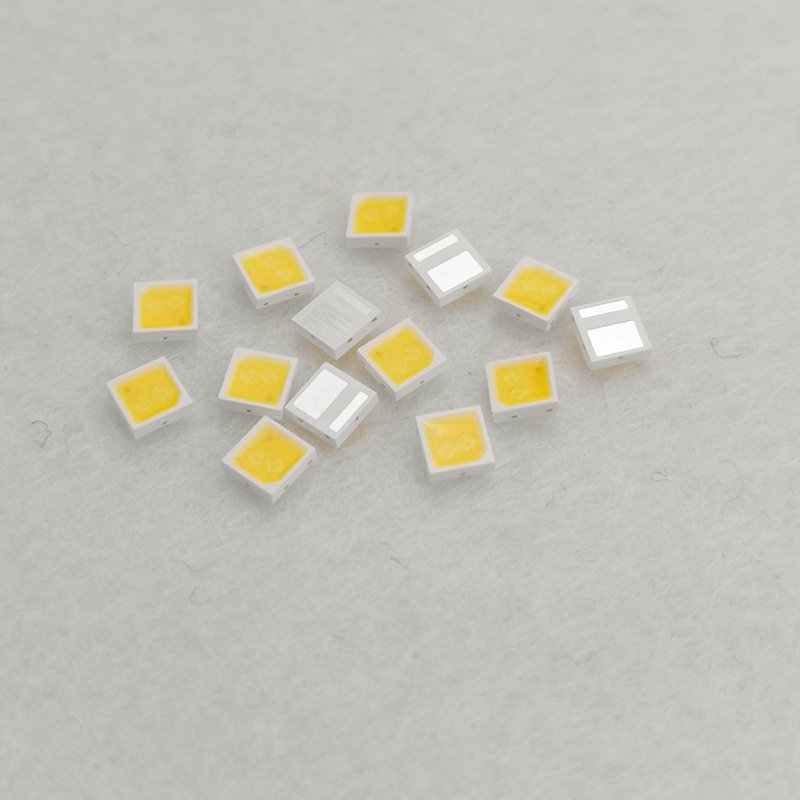

A. Definition of SMD (Surface Mounted Device)

SMD technology refers to the method of mounting LED chips directly onto the surface of a circuit board, with minimal use of wiring and interconnects. This design allows for compact, high-performance units that can be easily integrated into different lighting fixtures. Detailed guide on SMD technology.

Typical Applications in Street Lighting: SMD LEDs are often used in floodlights, street lamps, and tunnel lighting due to their high light output and efficient energy consumption. They provide a uniform light distribution, which is crucial for general street illumination.

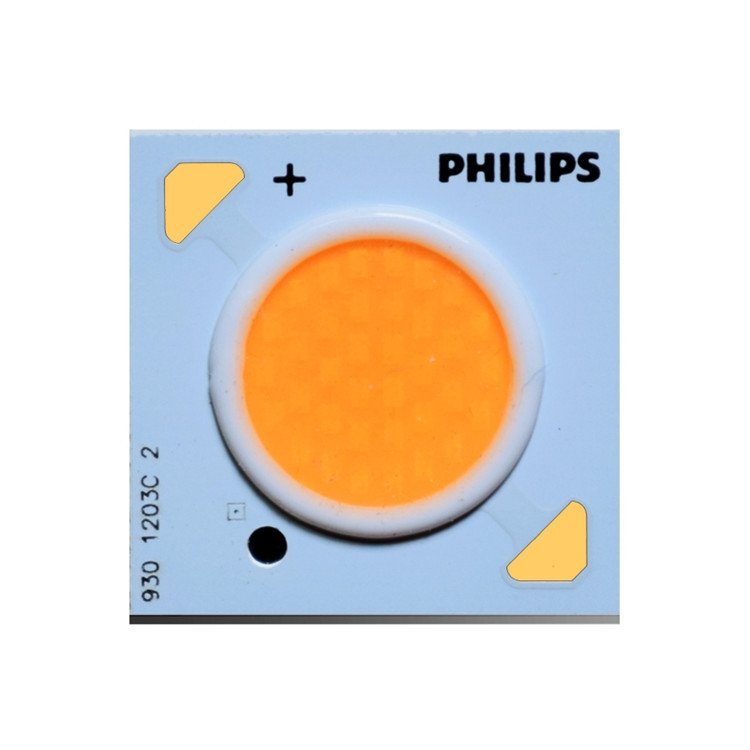

B. Definition of COB (Chip On Board)

COB technology involves placing multiple LED chips directly on a single substrate, resulting in a more compact light source. Unlike SMD, which typically uses one or more chips per package, COB integrates several chips in a single, densely packed unit, making it more powerful for focused applications. Introduction to COB LEDs.

Advantages in Various Lighting Scenarios: COB LEDs offer higher lumen output and more direct light, which makes them ideal for situations where concentrated light is necessary, such as in street lighting or high-intensity floodlighting.

3.1. Key Differences Between SMD and COB

A. Design and Size

COB: Larger and more robust design due to the integration of multiple chips in a single unit.

SMD: Compact, slim design that fits a variety of housing types and is flexible in installation.

Impact on Installation and Space Utilization: While SMD LEDs are smaller and more versatile in terms of installation flexibility, COB’s design requires more space but offers better light intensity and concentration, making it a good option for high-output needs. Explore LED design considerations.

B. Light Output and Beam Angle

SMD: SMD LEDs provide light that is more diffuse and evenly distributed, which is beneficial for applications requiring broad coverage, such as street lighting.

COB: COB LEDs offer a more focused light output, often with a narrower beam angle, which is suitable for targeted lighting needs such as street intersections or specific areas needing higher intensity.

Implications for Street Lighting: For street lighting, the wider beam angle of SMD ensures uniform illumination across longer stretches of road, while COB’s directed light may be better for highlighting specific areas or enhancing visibility at intersections. How beam angles affect street lighting performance.

C. Energy Efficiency

SMD: Generally, SMD LEDs are more energy-efficient at lower wattages and are often the choice for systems with moderate light requirements.

COB: COB LEDs, while more energy-intensive, provide higher light output per watt, which translates to greater energy efficiency in high-lumen applications.

Longevity and Maintenance Considerations: COB LEDs have a longer lifespan in high-demand scenarios, though both SMD and COB technologies can provide decades of service with minimal maintenance. LED lifespan studies.

4.1. Performance in Street Lighting Applications

A. Brightness and Visibility

Street lighting applications demand high brightness and clear visibility to ensure safety. COB LEDs excel in high-output environments, offering superior brightness with a more focused beam. SMD LEDs, on the other hand, provide more consistent and softer lighting, which is crucial for reducing glare and preventing light pollution in residential areas. Reducing glare in street lighting.

Glare Reduction: COB technology, due to its concentrated beam, can potentially cause more glare if not designed properly, while SMD ensures a more diffused and comfortable light distribution.

B. Durability and Lifespan

Both SMD and COB LEDs are highly durable, but COB’s higher efficiency and performance in demanding environments typically mean it outlasts SMD in high-usage scenarios, such as urban highways or busy intersections.

Environmental Suitability: COB LEDs are less sensitive to thermal buildup and are better suited for outdoor applications in harsher weather conditions. Thermal management in LEDs.

5.1. Cost Considerations

A. Initial Investment vs. Long-term Savings

SMD: While the initial investment for SMD-based systems can be lower, the long-term savings might not be as significant compared to COB due to slightly higher energy consumption and more frequent maintenance cycles.

COB: Higher initial costs can be offset by the technology’s superior energy efficiency and longer lifespan. In high-demand environments, COB can result in significant long-term savings. Cost analysis of LED systems.

Cost Analysis: Investing in COB could be more economical in the long run for urban municipalities looking to lower energy and maintenance costs, especially in large-scale installations.

6.1. Practical Applications in Urban Settings

A. Case Studies of SMD Use in Street Lighting

SMD technology has been successfully implemented in cities with wide, low-traffic streets, offering consistent illumination with reduced glare. For example, Singapore’s public lighting system relies heavily on SMD technology for general street lighting, balancing cost-effectiveness with performance. Singapore’s lighting case study.

B. Case Studies of COB Use in Street Lighting

COB technology is widely used in areas requiring high intensity, such as on major highways and at busy intersections. In Dubai, for instance, COB LEDs are used extensively in streetlights due to their ability to provide focused, high-intensity light that improves visibility and safety during nighttime driving. Dubai’s LED lighting case study.

7.1 What does SMD and SMT stand for?

A. SMD (Surface Mounted Device)

SMD refers to a method of mounting LED chips directly onto a circuit board without the need for additional leads or large packaging, enabling compact and versatile designs.

B. SMT (Surface Mount Technology)

SMT is the broader manufacturing process that incorporates SMD components. It involves placing and soldering surface-mounted components onto a PCB (Printed Circuit Board).

8.1 Is SMD better than LED?

A. SMD vs. Traditional LEDs

SMD is a type of LED technology. Traditional LEDs are generally less efficient and versatile compared to SMD LEDs, which offer:

- Higher brightness levels.

- Greater energy efficiency.

- Compact designs suitable for a range of applications.

B. Suitability

SMD LEDs are better than traditional LEDs for street lighting due to their superior performance, flexibility, and energy efficiency.

9.1 What does SMD mean for LED lights?

SMD technology revolutionized LED lighting by enabling the production of smaller, more efficient, and brighter light sources. It allows LEDs to:

- Provide uniform light distribution.

- Be used in a wide range of applications, from residential to industrial lighting.

10.1 What are the disadvantages of SMD LED?

A. Limitations

- Thermal Management: SMD LEDs can generate significant heat, requiring efficient heat sinks.

- Durability: They may not perform as well as COB LEDs in harsh environments.

B. Cost Implications

While SMD LEDs are cost-effective initially, their need for additional components, like drivers and heat sinks, can increase the overall cost.

11.1 What is brighter, COB or LED?

A. Brightness Comparison

COB LEDs are generally brighter than SMD LEDs due to their higher lumen density.

B. Application-Specific Brightness

- COB LEDs: Suitable for high-intensity, focused lighting applications like highways and intersections.

- SMD LEDs: Provide consistent brightness over larger areas, making them ideal for residential and general street lighting.

12.1 Understanding SMD and COB Technologies

A. Definition of SMD (Surface Mounted Device)

SMD technology refers to the method of mounting LED chips directly onto the surface of a circuit board, with minimal use of wiring and interconnects. This design allows for compact, high-performance units that can be easily integrated into different lighting fixtures. Detailed guide on SMD technology.

Typical Applications in Street Lighting: SMD LEDs are often used in floodlights, street lamps, and tunnel lighting due to their high light output and efficient energy consumption. They provide a uniform light distribution, which is crucial for general street illumination.

B. Definition of COB (Chip On Board)

COB technology involves placing multiple LED chips directly on a single substrate, resulting in a more compact light source. Unlike SMD, which typically uses one or more chips per package, COB integrates several chips in a single, densely packed unit, making it more powerful for focused applications. Introduction to COB LEDs.

Advantages in Various Lighting Scenarios: COB LEDs offer higher lumen output and more direct light, which makes them ideal for situations where concentrated light is necessary, such as in street lighting or high-intensity floodlighting.

13.1 Key Differences Between SMD and COB

A. Design and Size

SMD: Compact, slim design that fits a variety of housing types and is flexible in installation.

COB: Larger and more robust design due to the integration of multiple chips in a single unit.

Impact on Installation and Space Utilization: While SMD LEDs are smaller and more versatile in terms of installation flexibility, COB’s design requires more space but offers better light intensity and concentration, making it a good option for high-output needs. Explore LED design considerations.

B. Light Output and Beam Angle

SMD: SMD LEDs provide light that is more diffuse and evenly distributed, which is beneficial for applications requiring broad coverage, such as street lighting.

COB: COB LEDs offer a more focused light output, often with a narrower beam angle, which is suitable for targeted lighting needs such as street intersections or specific areas needing higher intensity.

Implications for Street Lighting: For street lighting, the wider beam angle of SMD ensures uniform illumination across longer stretches of road, while COB’s directed light may be better for highlighting specific areas or enhancing visibility at intersections. How beam angles affect street lighting performance.

C. Energy Efficiency

SMD: Generally, SMD LEDs are more energy-efficient at lower wattages and are often the choice for systems with moderate light requirements.

COB: COB LEDs, while more energy-intensive, provide higher light output per watt, which translates to greater energy efficiency in high-lumen applications.

Longevity and Maintenance Considerations: COB LEDs have a longer lifespan in high-demand scenarios, though both SMD and COB technologies can provide decades of service with minimal maintenance. LED lifespan studies.

14.1 Performance in Street Lighting Applications

A. Brightness and Visibility

Street lighting applications demand high brightness and clear visibility to ensure safety. COB LEDs excel in high-output environments, offering superior brightness with a more focused beam. SMD LEDs, on the other hand, provide more consistent and softer lighting, which is crucial for reducing glare and preventing light pollution in residential areas. Reducing glare in street lighting.

Glare Reduction: COB technology, due to its concentrated beam, can potentially cause more glare if not designed properly, while SMD ensures a more diffused and comfortable light distribution.

B. Durability and Lifespan

Both SMD and COB LEDs are highly durable, but COB’s higher efficiency and performance in demanding environments typically mean it outlasts SMD in high-usage scenarios, such as urban highways or busy intersections.

Environmental Suitability: COB LEDs are less sensitive to thermal buildup and are better suited for outdoor applications in harsher weather conditions. Thermal management in LEDs.

15.1 Conclusion

Both SMD and COB LED technologies offer unique advantages for street lighting, and the choice between them depends on specific application needs. SMD is ideal for general lighting due to its uniform light distribution and cost-effectiveness. COB, however, excels in scenarios requiring high light output and focused illumination, offering superior performance for high-demand environments.

Recommendations for Municipalities:

For areas requiring broader, softer light (e.g., residential streets), SMD technology is a cost-effective solution.

For highways, intersections, and other high-traffic areas, COB technology is the better choice due to its high lumen output and focused beam.

16.1 Future Trends in LED Street Lighting

The future of LED street lighting lies in continued innovation, with emerging technologies like smart street lights and adaptive lighting systems poised to make a significant impact. These systems will leverage both SMD and COB technologies, combining their strengths to meet the evolving needs of urban environments. Smart street lighting innovations.

As cities push for more sustainable and energy-efficient solutions, COB LEDs may gain more prominence in applications demanding high brightness and performance, while SMD LEDs will remain popular for general, cost-effective lighting.